Meet the Meltio

MPS500

From Wire to Part.

Seamlessy.

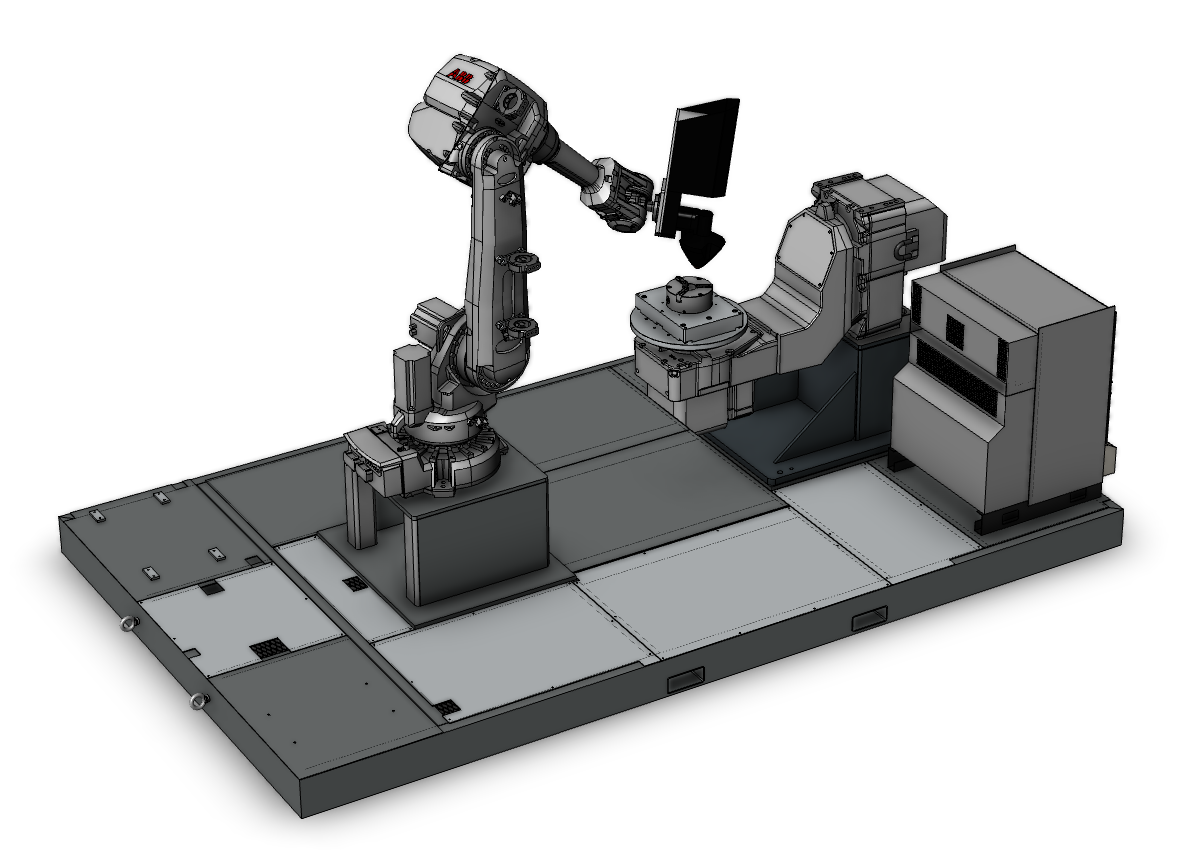

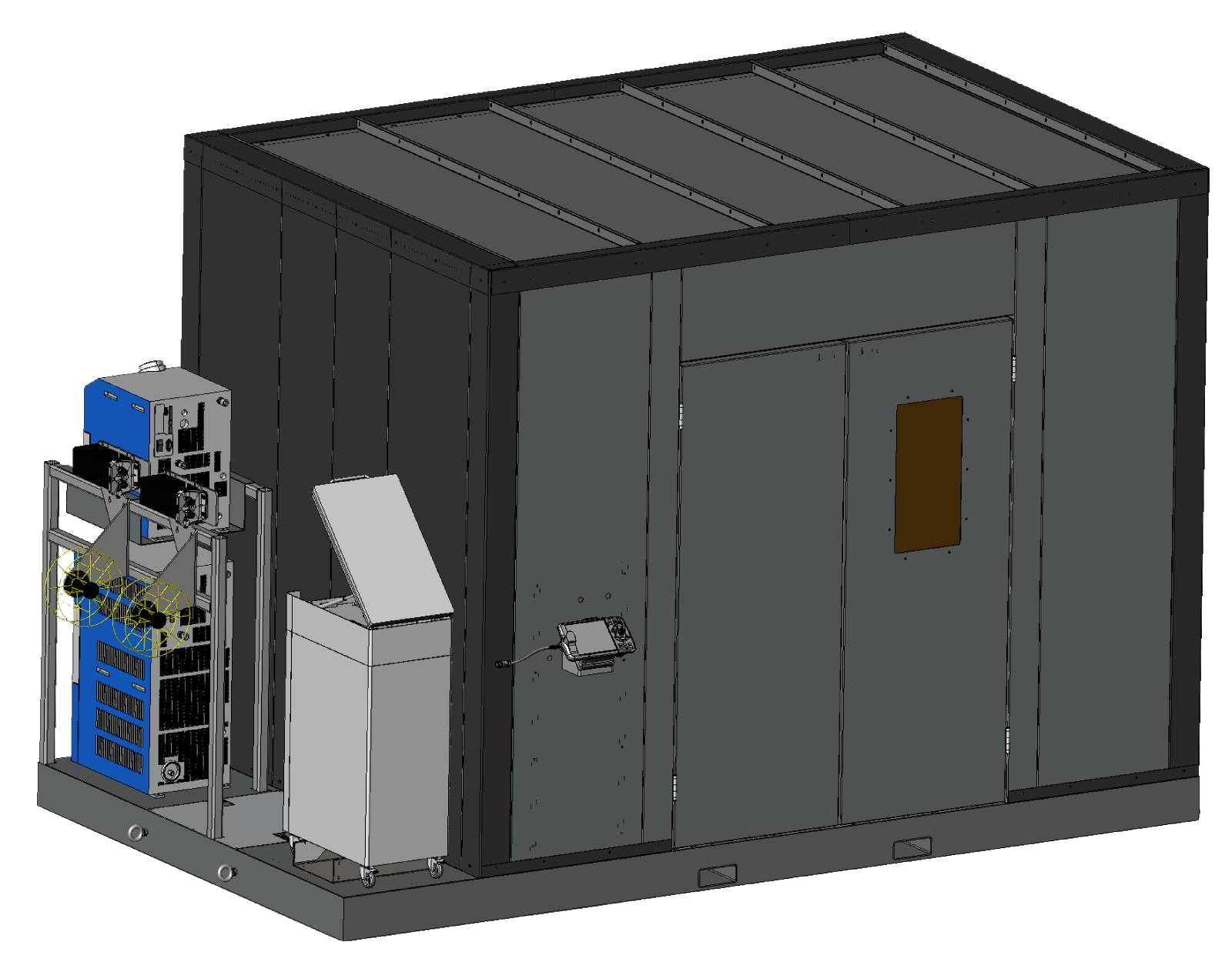

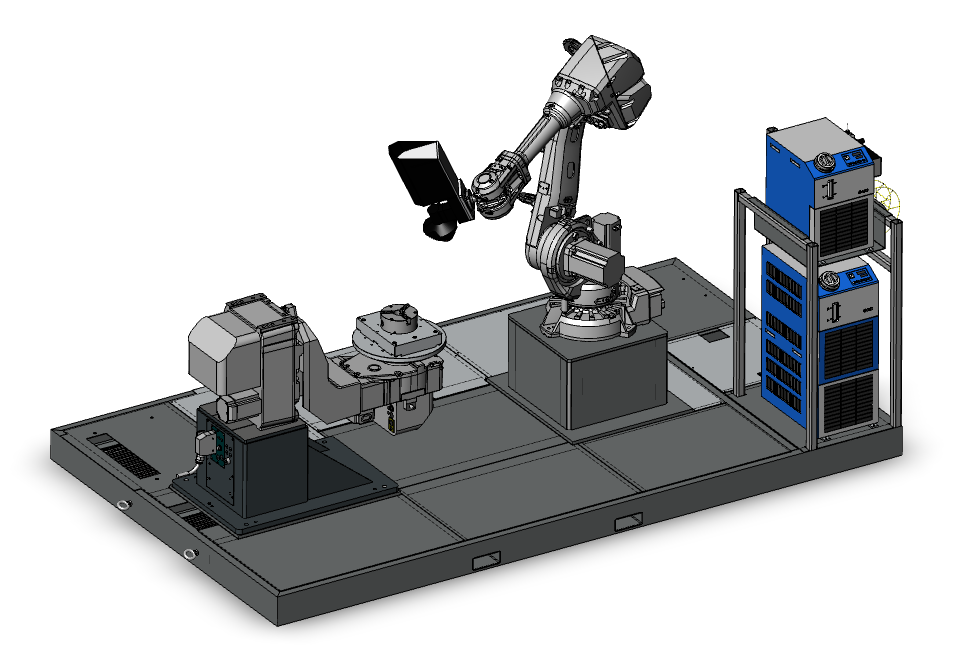

The MPS500 is a fully enclosed, turnkey metal 3D printing cell built for precision, reliability, and ease of use. Powered by Meltio’s wire-laser DED technology and an ABB 6-axis robotic arm, it’s engineered to handle complex geometries and a wide range of alloys with ease. Having integrated safety features, a multi-axis build platform, and Meltio Space software compatibility, the MPS500 is ready to print the moment it hits your floor. No setup, no compromise; just industrial-grade metal additive manufacturing, simplified.

A fully enclosed, self-contained system that includes everything you need to start printing. Clean, safe, and production-ready from day one.

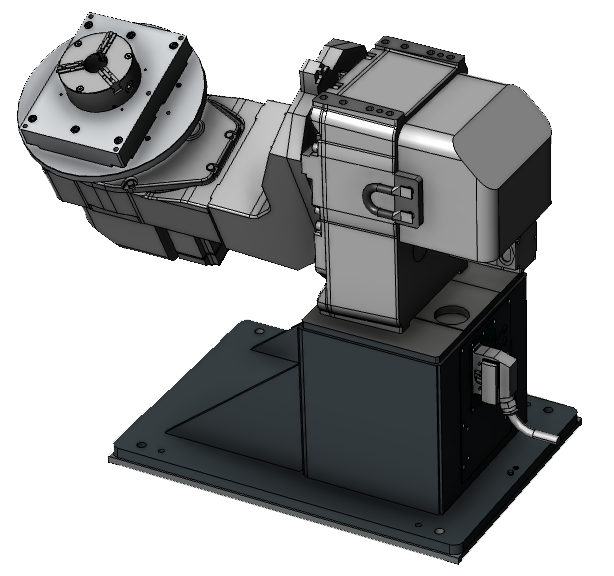

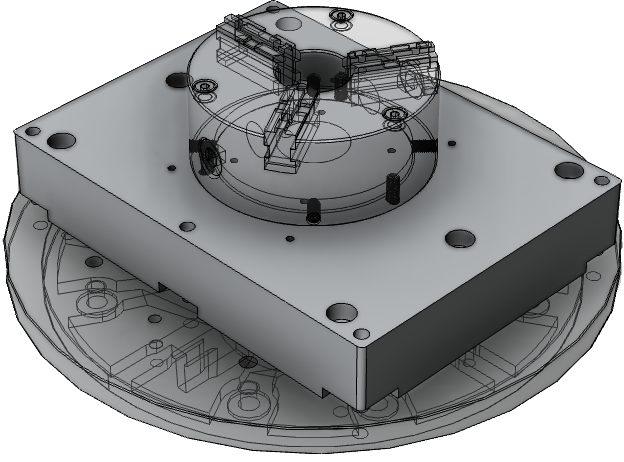

The integrated multi-axis build platform allows for advanced part orientation, optimized toolpaths, and complex geometry printing.

Designed to move with the robot to enable full freedom of motion & consistent quality across every layer.

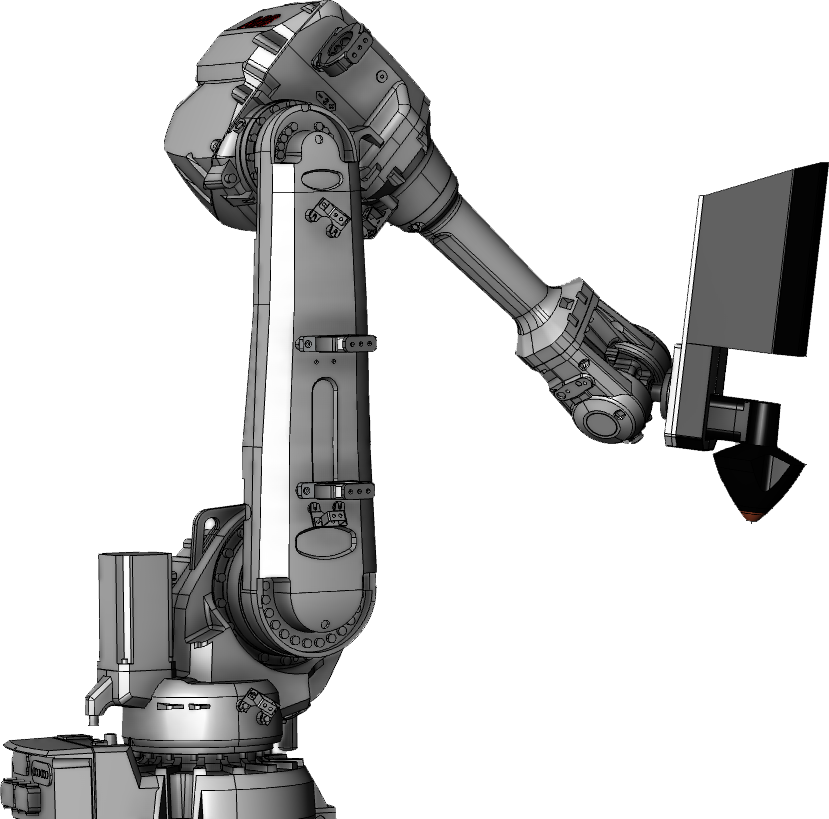

The MPS500’s wire-laser deposition head delivers precise, multi-material metal printing with consistent, high-quality layer fusion across every build.

Key Tech Features

Cell Size

13 ft x 8ft x 10ft

Laser System

1200W

6 x 976 nm

Direct Diode Lasers & Fibers & Colimators

Materials

Stainless Steel

Carbon Steel

Titanium

Copper & Gold & More

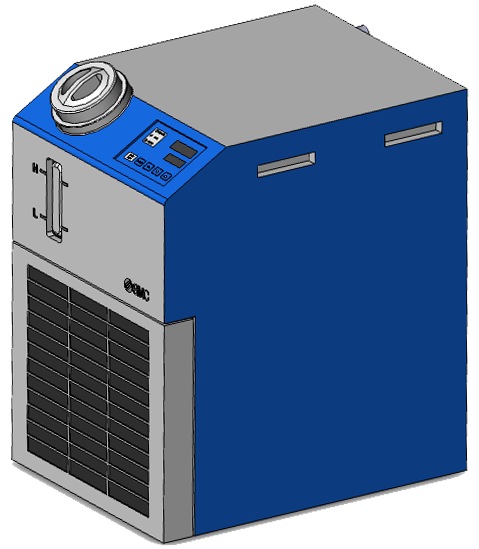

Cooling

Closed loop water cooled chiller included.

Upgrades Available.

Max Weight

Holds up to 1100lbs

Electrical

200 240V 3W PE

2 to 5 kW Peak

Laser System:

Infrared laser

1200W 6 x 976 nm direct diode lasers + fibers & colimators

Printhead:

15.5 kg

Printhead Size (WxDxH):

230 x 310 x 710 mm

Control Unit:

Floor Mounted (Wheeled) 125k with 27″ HMI

390 x 650 x 1600 (deployed screen)

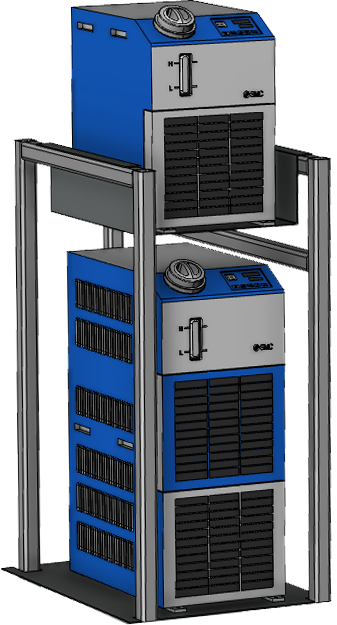

Cooling:

Water-cooled control unit and deposition head. Chiller included

Print Envelope:

Depending on robot’s reach

Process Control:

Closed-loop, wire modulation

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

2 – 5 kW peak depending on selected options

Slicer Software:

Meltio Space 1-year subscription Included

Feeder System:

Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners

Wire Feedstock:

Diameter: 0.8-1.2mm / Spool Type: 8S300

External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials: Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more.

Keep Cool

Even Under Pressure

Enhance your build quality with the optional active cooling bed upgrade—engineered to regulate substrate temperatures throughout the printing process. This upgrade minimizes warping, improves adhesion, and enables better thermal control for heat-sensitive or large-format metal parts. It’s ideal for maintaining dimensional accuracy in high-performance applications.

Stay Ice Cold

Upgrade to a dual-chiller system for enhanced thermal control during long or high-power builds. This optional second unit boosts cooling efficiency, reduces heat fatigue on components, and ensures consistent deposition even in the most demanding metal print jobs. Perfect for extended production runs or working with heat-intensive materials.