3D Printing

Meet Meltio

The Industry Leading

Additive Manufacturing System

Seamless Integration.

That’s Meltio.

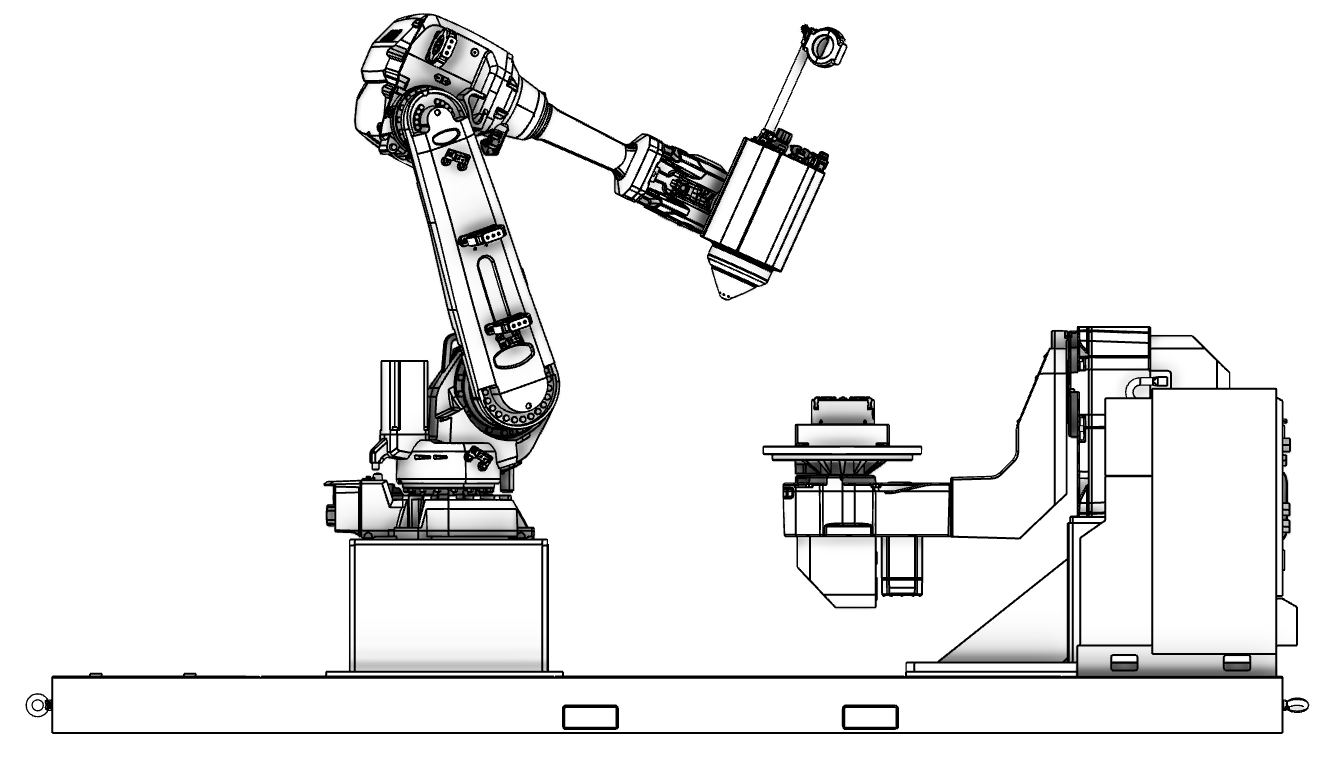

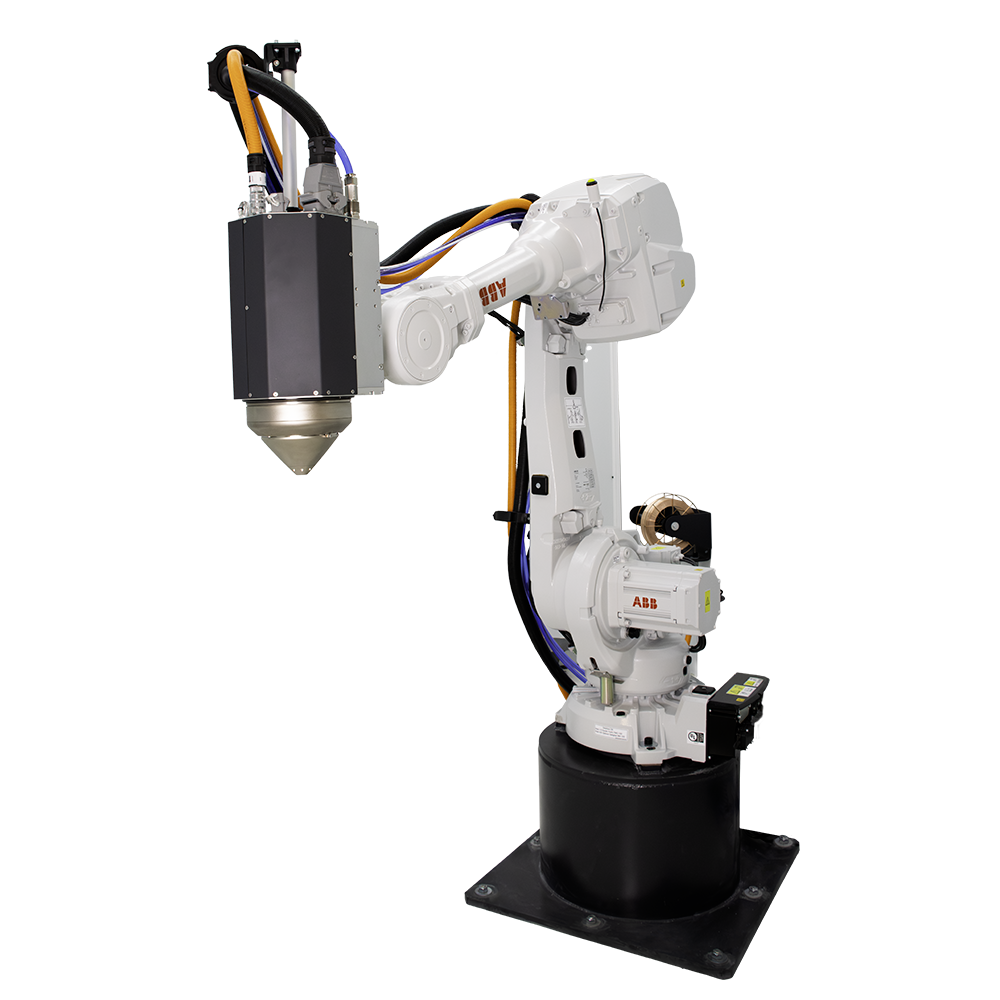

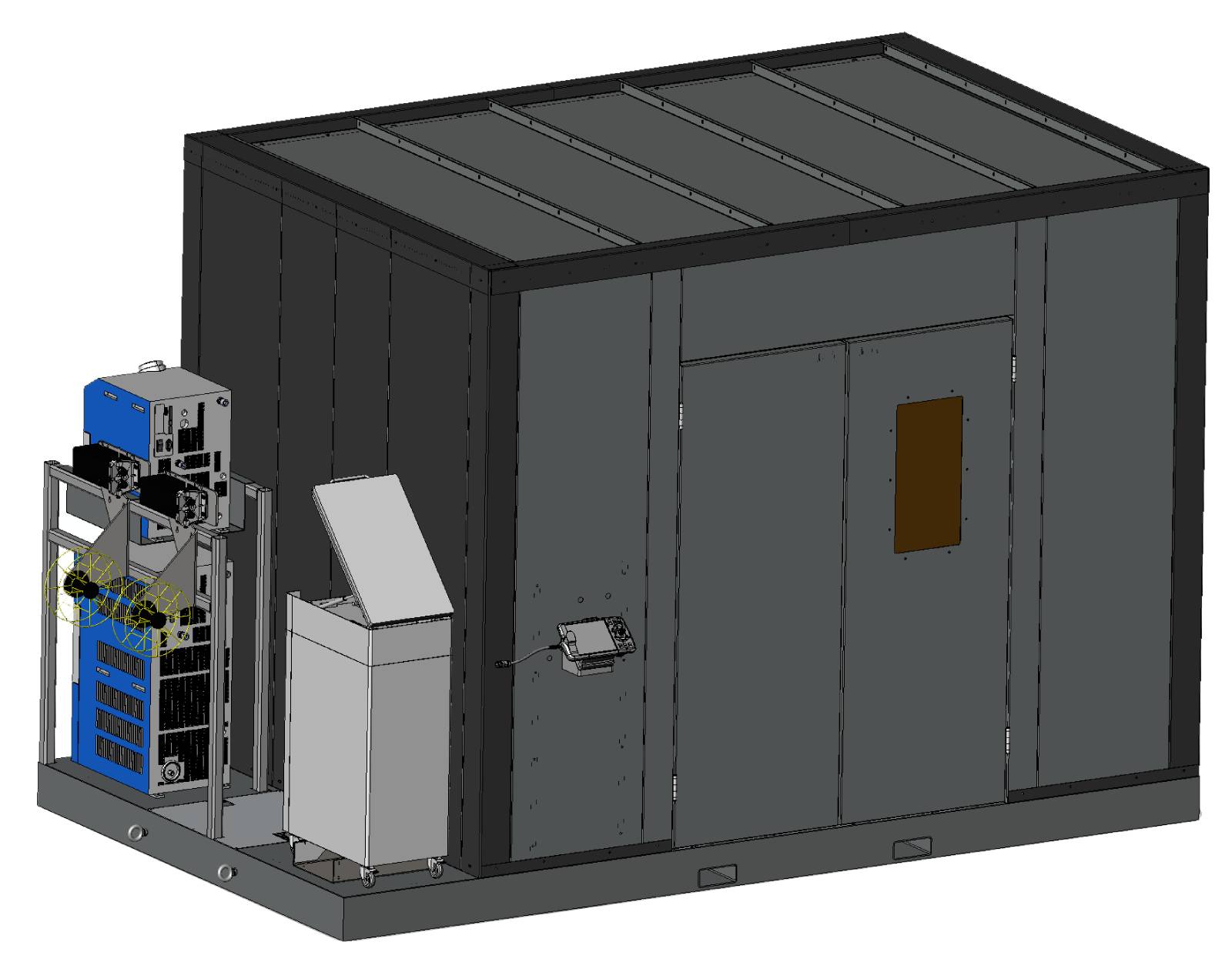

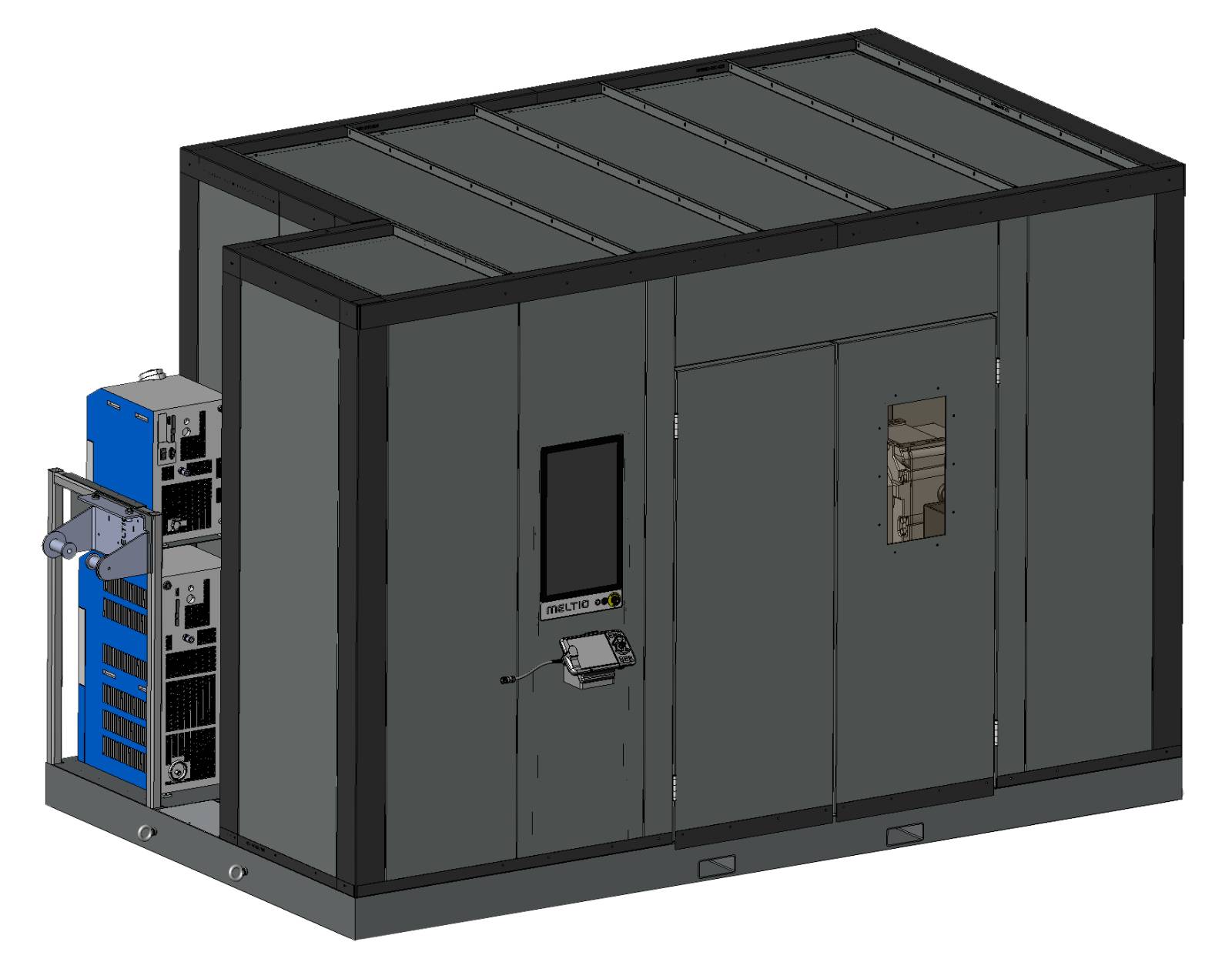

Introducing the Meltio Robot Cell – a fully enclosed, turnkey metal 3D printing solution engineered for precision, power, and simplicity. It’s everything you need to start printing complex metal parts – no setup, no compromise. Designed for manufacturers who demand control, flexibility, and results from day one.

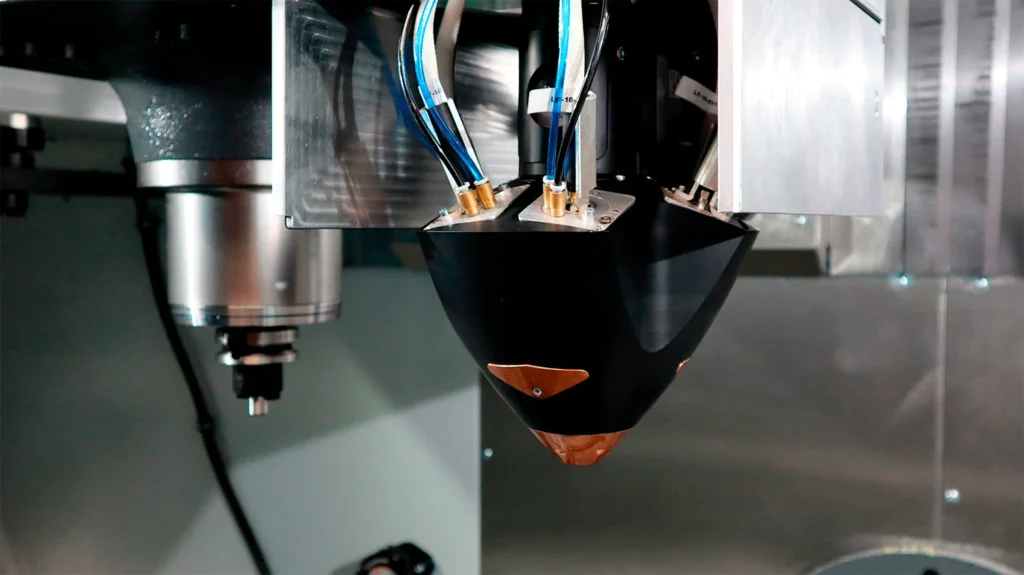

By integrating Meltio’s wire-laser DED technology with ABB’s proven industrial automation platform, each cell offers precise multi-axis movement for complex geometries and large-scale additive builds.

This synergy enables high-performance part production with optimized path control, consistent layer deposition, and reduced material waste. Ideal for aerospace, defense, and high-mix manufacturing environments.

MPS500

Turnkey metal printing.

No setup. Just press print.

Infrared Laser

1200W 6 x 976 nm direct diode lasers + fibers & colimators

Detached control unit

Closed loop, wire modulation

MPS500B

Bluelight precision.

Sharper, cleaner builds.

Blue Laser

1000W 9 x 450 nm direct diode lasers

Onboard control unit

Wall Mounted, Air Cooled.

Melt Pool Camera & Closed-loop wire modulation

Efficiency, Redefined.

Designed for rapid deployment and minimal operator input, these systems streamline workflows, reduce setup time, and maximize material utilization—delivering faster, smarter production for complex metal parts.

Material Versatility

Our system supports a wide range of welding wire formats. Ideal for both prototyping and full-scale production

Minimal Oversight

Automated monitoring and process control reduce the need for hands-on supervision. It’s a smarter use of shop-floor labor.

Hybrid Ready System

Seamlessly integrate with subtractive systems for hybrid workflows. Perfect for part repair, enhancement, and finishing.

Consistent Results

Closed-loop control ensures layer-by-layer accuracy. Once a process is dialed in, it stays locked. You get reliable parts, batch after batch.

Rotary Screw Compressor

SS316L

Size:

75 x 75 x 230 mm cladded

Weight:

3 kg

Print Cost:

$ 62.83

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Print Cost:

$ 142.02

Spherical Tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Print Cost:

$ 433.07

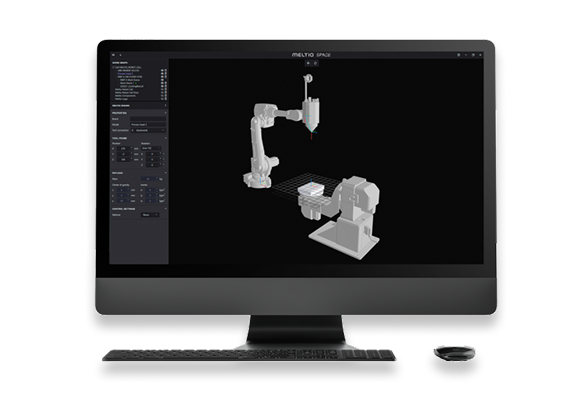

Meltio Space

The Brain Behind the Build.

Designed for rapid deployment and minimal operator input, these systems streamline workflows, reduce setup time, and maximize Meltio Space is the intuitive path-generation software behind every robotic Meltio build. Designed to turn complex geometries into streamlined, collision-free toolpaths with just a few clicks. With native support for ABB, KUKA, FANUC, and Yaskawa, it brings wire-laser metal 3D printing to life through elegant control, real-time simulation, and effortless cell configuration. No coding. No guesswork. Just perfect prints—every time.