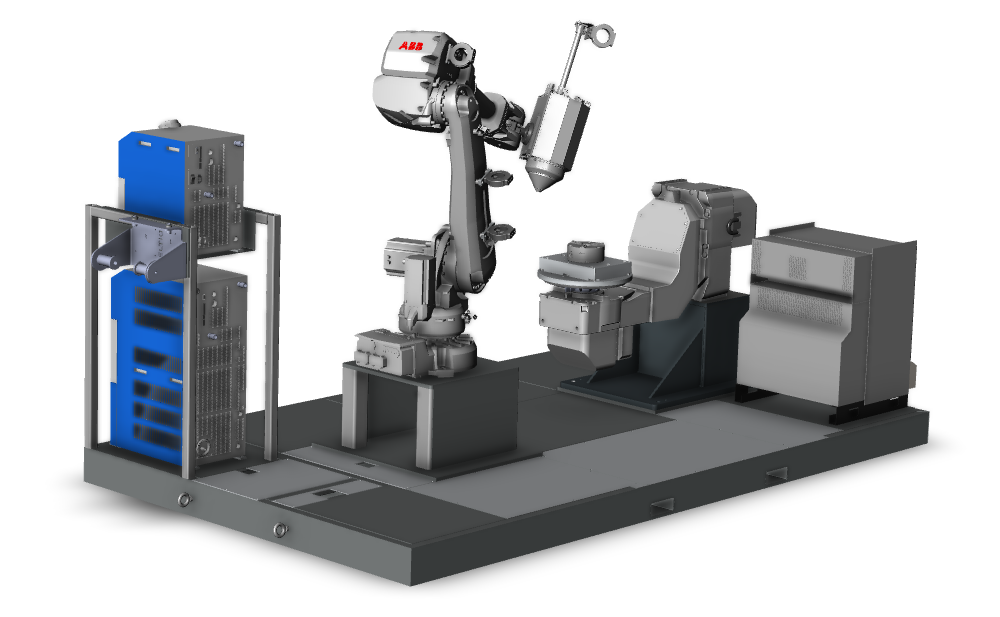

Meet the Meltio

MPS500B

Shorter Wavelength.

Higher Precision.

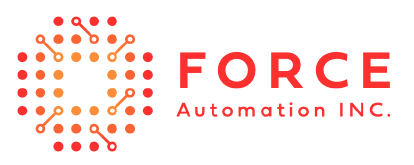

The next evolution in metal 3D printing. Powered by bluelight laser technology and built on FORCE Automation’s proven turnkey platform, the MPS500B delivers unmatched precision, superior material control, and flawless results in even the most reflective metals. Fully enclosed, robot-driven, and production-ready — it’s everything the future of manufacturing should be.

A fully enclosed, self-contained system that includes everything you need to start printing. Clean, safe, and production-ready from day one.

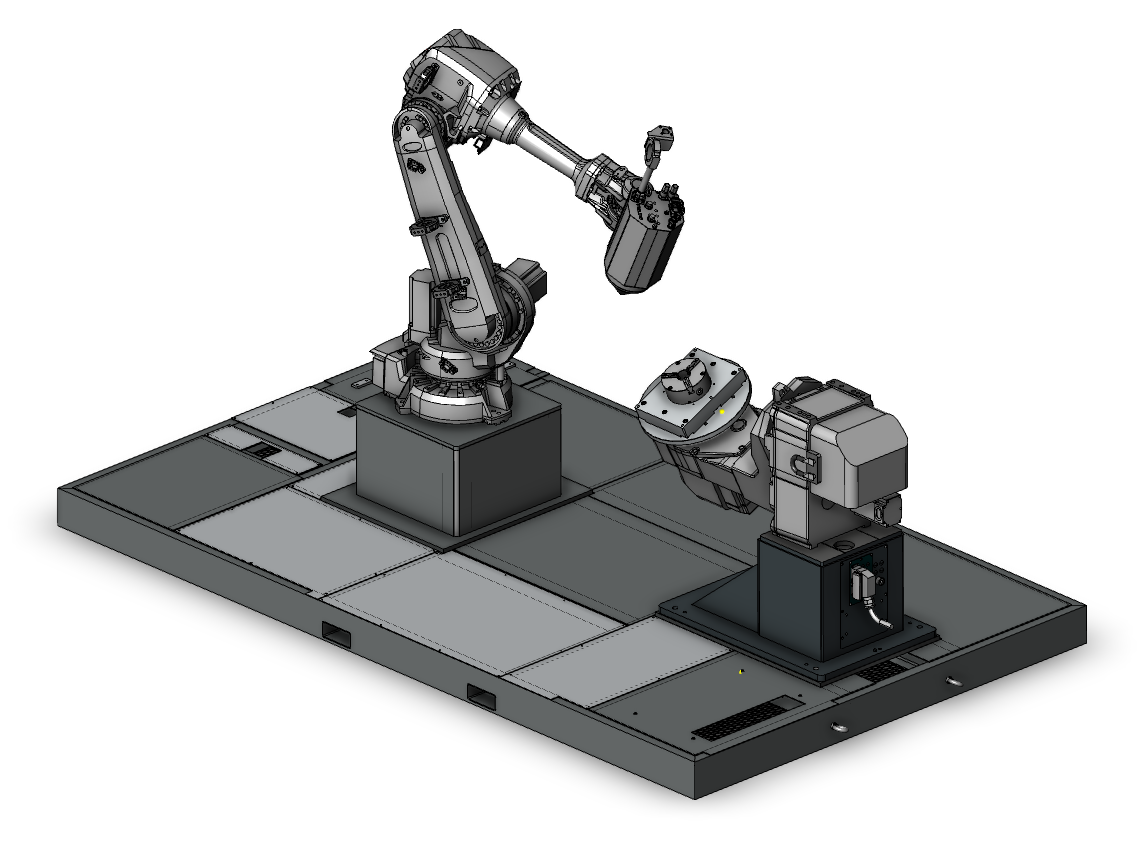

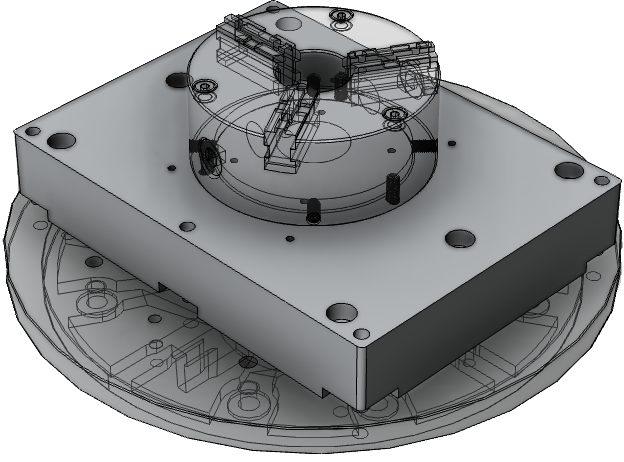

The integrated multi-axis build platform allows for advanced part orientation, optimized toolpaths, and complex geometry printing.

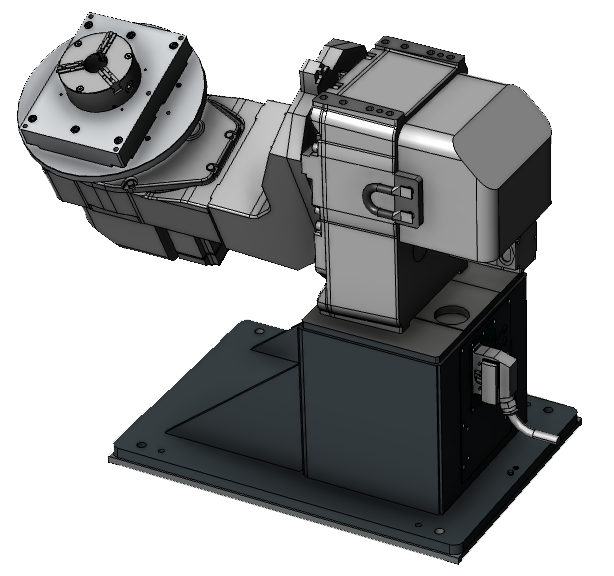

Designed to move with the robot to enable full freedom of motion & consistent quality across every layer.

The Bluelight Laser Deposition Head harnesses a shorter 450 nm wavelength for superior energy absorption in reflective metals like copper and aluminum.

Key Tech Features

Cell Size

13 ft x 8ft x 10ft

Laser System

1000w

9 x 450nm

Direct Diode

Lasers

Materials

Nickel Alloys

Steel Alloys

Titanium

Copper, Gold

& More

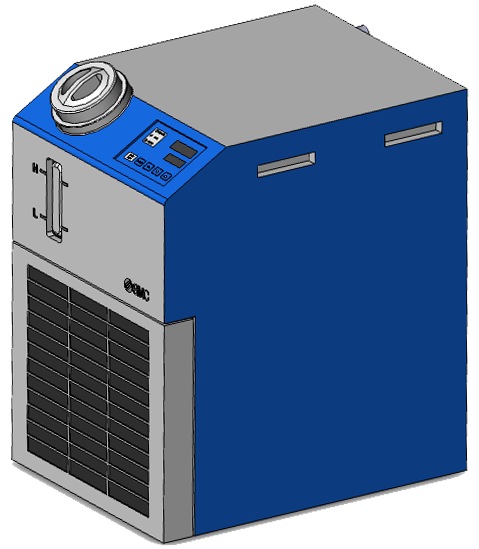

Cooling

Closed loop

water cooled

chiller included

Max Weight

Holds up to 1100lbs

Electrical

200 240V

3W PE

9kW Peak

2 5 kW Avg

Laser System:

Blue Laster (Higher absoprtion and power efficient; wider range of compatible materials than IR)

1000W 9 x 450 nm direct diode lasers

Printhead:

Robot Mounted 20.5 to 23 kg

Printhead Size (WxDxH):

262 x 272 x 572 mm

Control Unit:

Wall mounted, air-cooled 80.5 kg 600 x 300 x 800 mm. Separate wall mounted 27″ HMI

Cooling:

Water-cooled deposition head. Chiller Included.

Print Envelope:

Depending on robot’s reach

Process Control:

Melt Pool Camera & Closed-loop, wire modulation

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

9.2 kW peak 2-5 kW avg.

Slicer Software:

Meltio Space 1-year subscription included

Feeder System:

Quad-point traction servomotor feeder, frictionless liners

Wire Feedstock:

Diameter: 0.8-1.2mm / Spool Type: 8S300

External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials:

Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold Alloys, and more.

Keep Cool

Even Under Pressure

Enhance your build quality with the optional active cooling bed upgrade—engineered to regulate substrate temperatures throughout the printing process. This upgrade minimizes warping, improves adhesion, and enables better thermal control for heat-sensitive or large-format metal parts. It’s ideal for maintaining dimensional accuracy in high-performance applications.

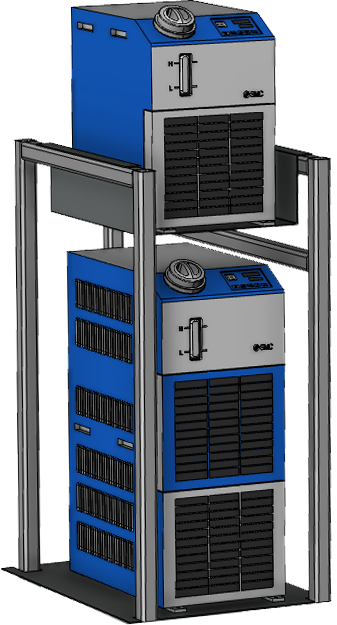

Stay Ice Cold

Upgrade to a dual-chiller system for enhanced thermal control during long or high-power builds. This optional second unit boosts cooling efficiency, reduces heat fatigue on components, and ensures consistent deposition even in the most demanding metal print jobs. Perfect for extended production runs or working with heat-intensive materials.