Products

Turn key solutions for any manufacturing processes

What we do

Force Automation Inc. provides turn key solutions for any of today’s manufacturing processes. Our skilled engineers design completely integrated work cells that can combine many process steps into a single automated platform. Process step integration saves on floor space and cycle times as component handling requirements are reduced.

How we do it

All products are run-off for customer acceptance, per specification, prior to shipping. All systems include fully integrated worker safety features and are dust collection ready. Each installation comes with one year license for Robot Studio, allowing customers to add custom routines and increase utilization on their own. Easy to use HMI, full user training, and long term customer support keep systems running at the customer facility after install. After-sale programming support is also available on or off site.

Real challenges. Real solutions.

What we offer

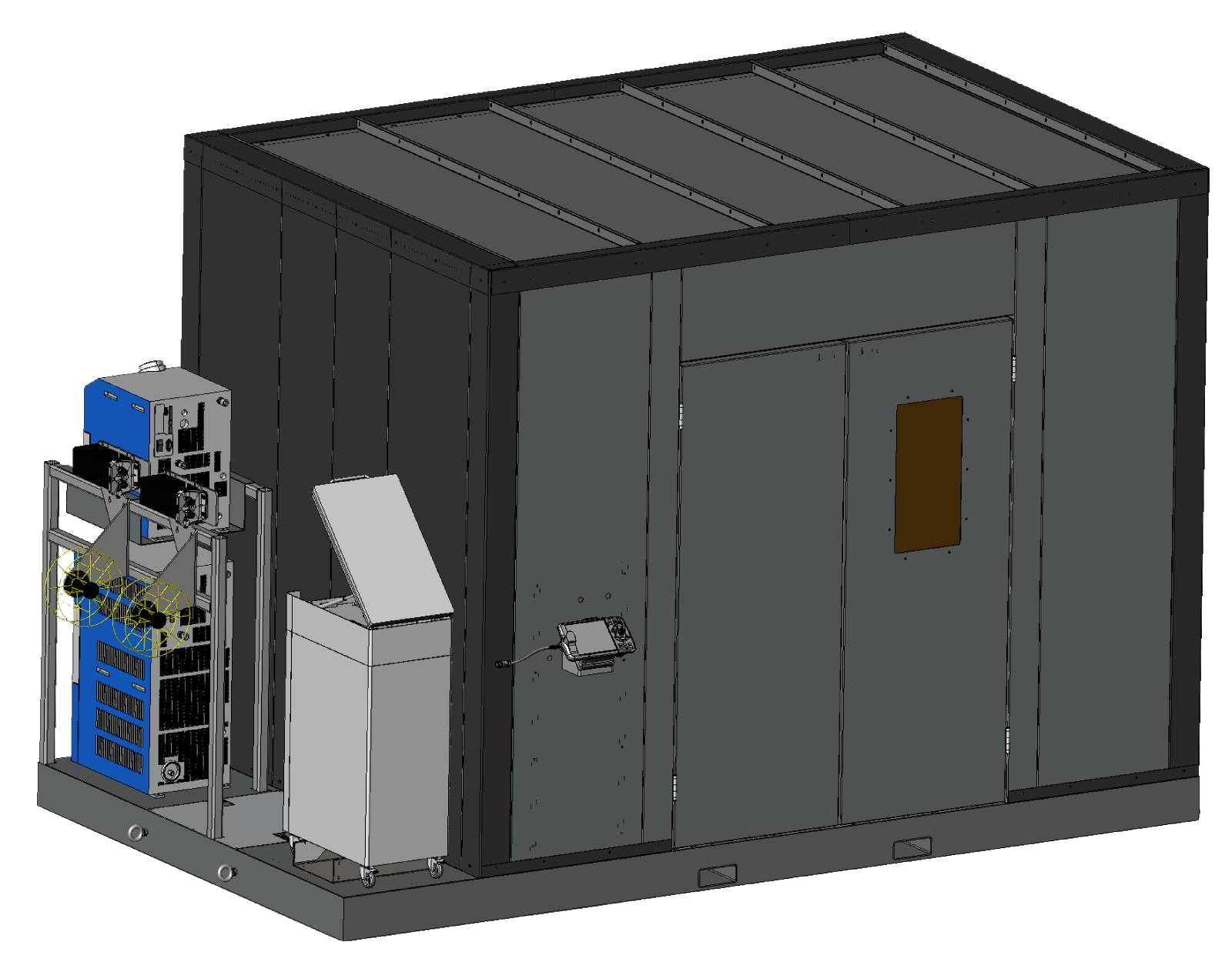

Standard Work Cell Configuration

LTS 5

Contact us for more info

LTS 7

Contact us for more info

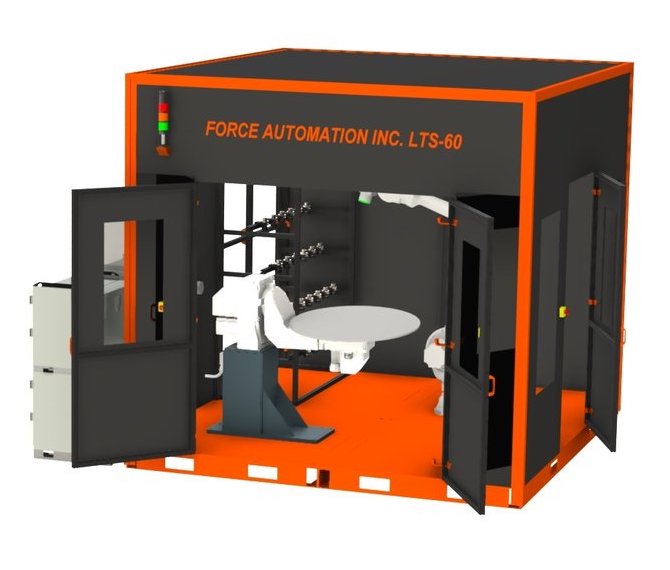

LTS 60

Contact us for more info

Automated Blasting Cell

MLB 650

Contact us for more info

MLB 750

Contact us for more info

MLB 4000

Contact us for more info

Automation Tooling

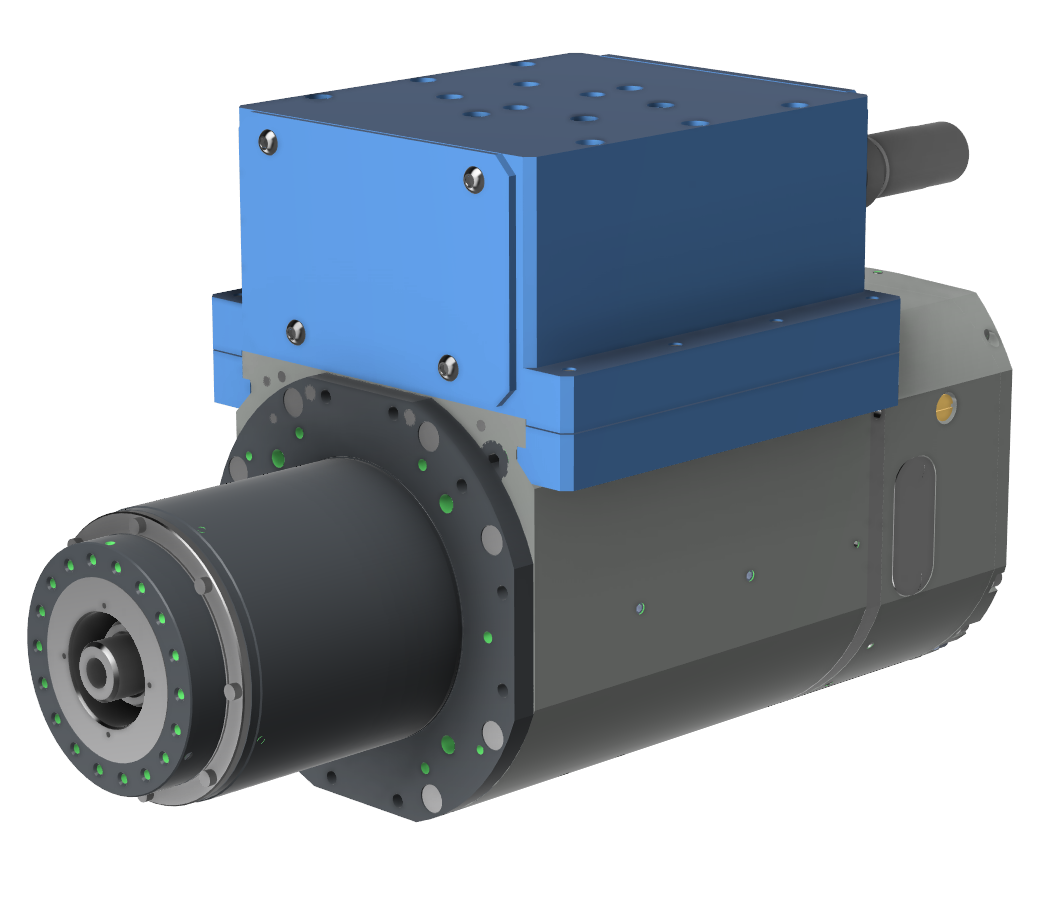

Spindle

Contact us for more info

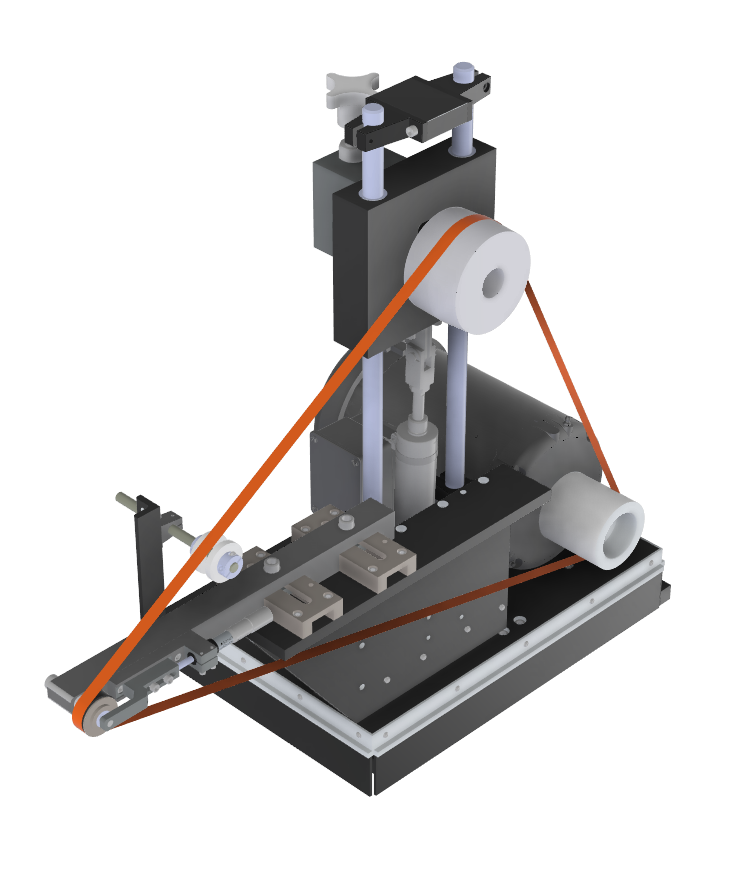

FAB 3S

Belt Unit

Contact us for more info